HOME > Product Info > Product

Product

- Fuel cell and ESS(Energy storage system)

1. Catalyst

2. Bioplar plate : Graphite plate, Metal plate

3. MEAs

Bipolar plate Application guide

| Item | Application | CO-103 | CO-134 | CO-962 | CO-573 | CO-652 | CO-653 | CO-136 |

|---|---|---|---|---|---|---|---|---|

| Fuel Cells | PEMFC (Low-temp) |

● | ● | ● | ||||

| PEMFC (high-temp) |

● | |||||||

| PAFC | ● | |||||||

| DMFC | ● | ● | ||||||

| Redox Flow Battery | Vanadium | ● | ● | ● |

Bipolar plate for Fuel Cell

| Properties | Unit | CO-103 | CO-134 | CO-962 | CO-573 |

|---|---|---|---|---|---|

| Density | g/㎤ | 1.92 | 2.00 | 1.89 | 2.1 |

| Shore Hardness | Hs | 29 | 25 | 29 | 34 |

| Flexural Strength | Mpa | 45 | 40 | 48 | 38 |

| Electrical conductivity | S/㎝ (In-plane) | 115 | 178 | 105 | 107 |

| S/㎝ (Through-Plane) | 68 | 85 | 62 | 58 | |

| Glass Transition Temp | ℃ | 180 | 120 | 180 | 230 |

| Gas (H2) permeability | ㎝/sec∙atm | 1.13 x 10-6 | 7.51 x 10-7 | 1.23 x 10-6 | 1.25 x 10-6 |

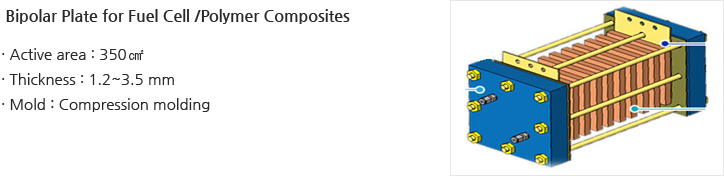

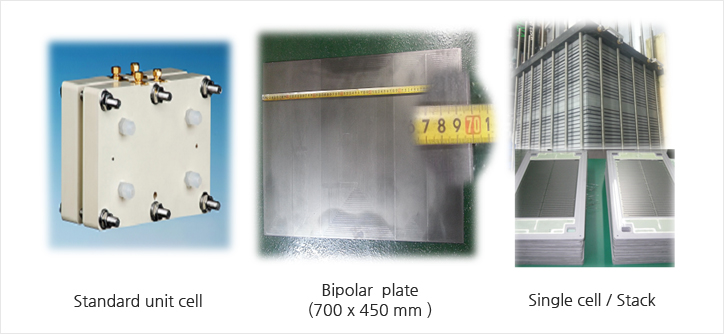

Mold-To-Size

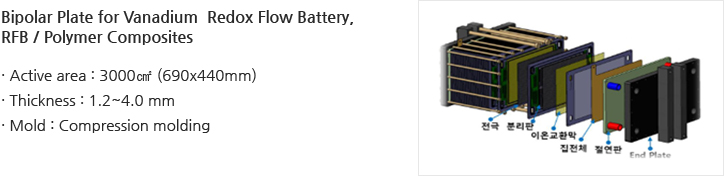

Bipolar plate for VRFB

| Properties | Unit | CO-652 | CO-653 | CO-136 |

|---|---|---|---|---|

| Density | g/㎤ | 2.0 | 2.0 | 2.1 |

| Shore Hardness | Hs | 20 | 22 | 28 |

| Flexural Strength | Mpa | 38 | 40 | 42 |

| Electrical conductivity | S/㎝ (In-plane) | 112 | 116 | 165 |

| S/㎝ (Through-Plane) | 65 | 72 | 80 | |

| Glass Transition Temp | ℃ | 65 | 65 | 120 |

| Gas (H2) permeability | ㎝/sec∙atm | 1.15 x 10-6 | 1.22 x 10-6 | 7.83 x 10-7 |

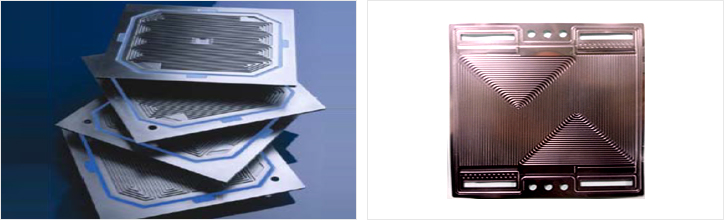

Metal bipolar plate for FCV

[ Metal bipolar plate ]

· Sharing the anode and cathode electrodes of metal separator plates

· Thickness : 0.1mm or less

· Weight : less than 50 gram

· Over 40 years of press forming technology

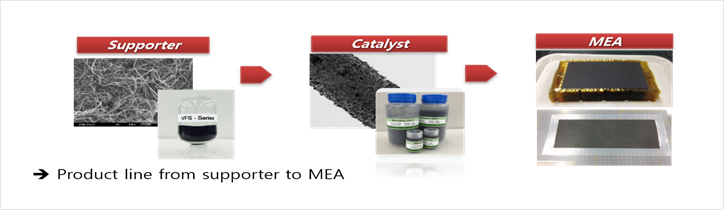

MEAs

| CORE TECHNOLOGY | |

|---|---|

| Slurry/Electrode · Ionomer nano-dispersion · Higher Pt utilization · High power performance & durability |

Catalyst design · High activity of Pt alloy catalyst · Anti-corrosion graphene support · Durable anode catalyst |

| Interfacial Layer · Strong interfacial adhesion · Higher mechanical durability · Improved proton transfer through the interface |

Manufacturing · -6 units processes · Process standardization · Capability of 150k cells/year |

| ITEM | STATIONARY | TRANSPORTATION | HT-PEM | TAILORED MEA |

|---|---|---|---|---|

| OPERATION CONDITION | 60 ~ 80 degrees, RH = 50 ~ 100% |

60 ~ 80 degrees, RH = 30 ~100% |

140 ~ 160 degrees, RH = ~100% |

~ 80 degrees, RH = ~ 100% |